Welding and cutting is a kind of hot working technology in the mechanical and electrical industry. It refers to a kind of hot working technology of mechanical and electronic manufacturing which combines solid materials and solid materials after local heating and melting.

The air pollution produced in the welding process, that is, the welding fume. The types and properties of harmful substances and gases in the welding fume produced in different welding process places are quite different from those in mathematics and physics.

The smoke produced by welding and cutting will cause health problems and affect production. The result is a decline in capacity, a return to disruption, and ultimately a reduction in profits. It's not just that the welder is in an unsafe environment. Production equipment, as well as final products, will also be negatively affected by inadequate safety measures.

Pollution hazards

During welding, arc discharge produces a lot of smoke and dust at the same time of melting electrode and weldment, which contains a lot of heavy metal harmful substances such as manganese, copper, Fe2O3, etc.

Dedusting solution

For the welding and cutting process, there are the following three treatment methods, for your reference, each enterprise usually adopts the traditional overall air exchange method. For the welding fume containing heavy metal particles, the effect is very poor, only the dilution dust concentration is enough, and the workshop is still "surrounded by clouds".

1. Improve the process

Adopt smoke-free and less smoke welding process, use low dust and low toxic welding materials to provide welding mechanization and automation.

2. Ventilation and smoke exhaust

Ventilation means that the air in the workshop and the air outside the workshop keep a good circulation. Through the flowing air flow, the welding smoke and dust can be quickly improved and flow out of the workshop together with the air. However, ventilation can play a certain role in reducing the welding fume in the workshop, and the effect is not ideal for the workshop with large amount of welding fume and fume.

3. Flue Dust TReatment

Compared with ventilation, dust removal is more effective for the collection and centralized treatment of welding fume. By installing the suction head at the welding point or the position where the welding fume is generated, before the welding fume has not spread in a large range, it will be inhaled into the central welding fume purification host, and the clean air will be discharged after filtering.

Moland's four treatment schemes of welding fume

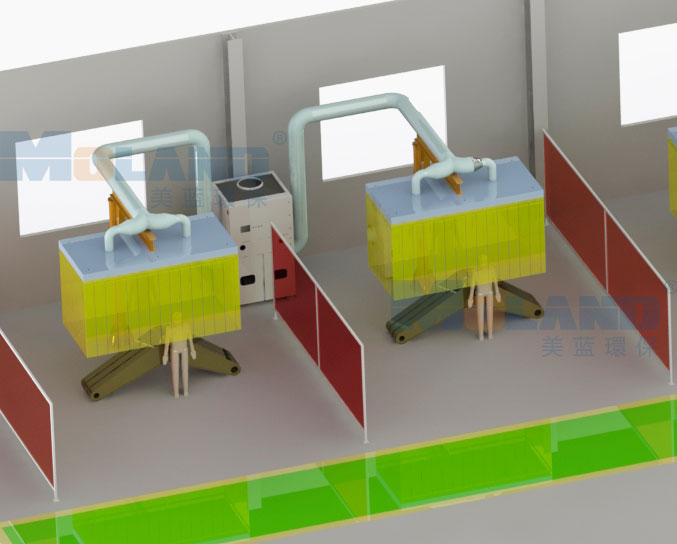

Suction hood type

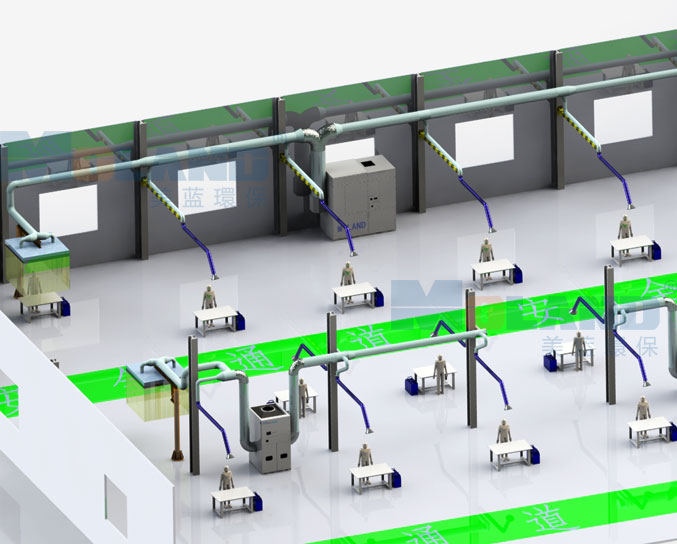

2. Cantilever type

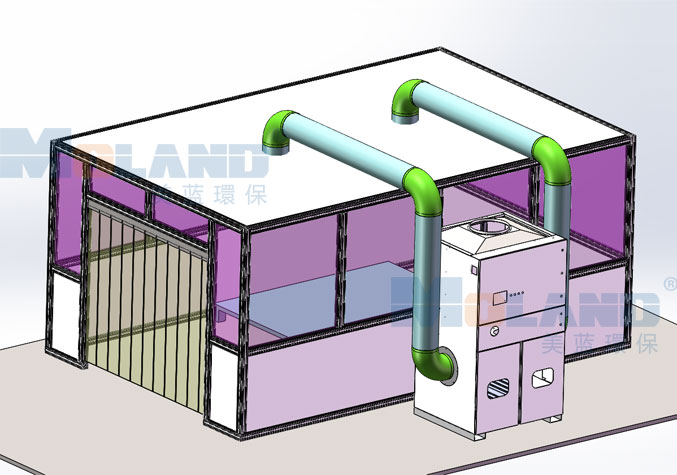

3. Room type

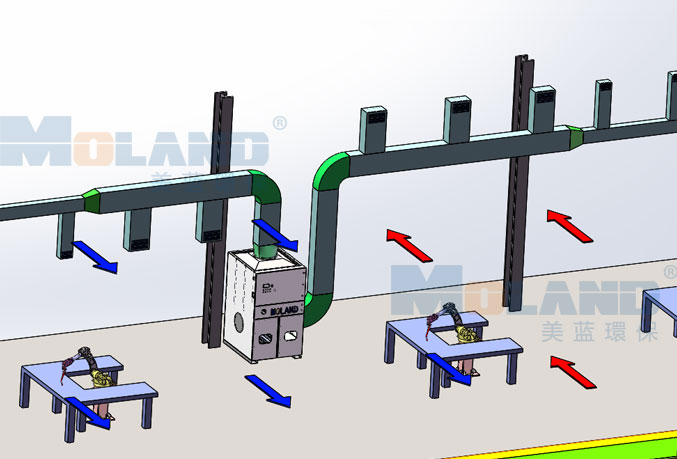

4. Blow suction

According to the welding quantity and workshop facilities, the enterprise should choose the proper way to deal with the welding fume, and arrange the dust removal equipment to achieve the ideal effect.